Aragio’s wide portfolio of general-purpose I/Os is targeted to meet the critical performance, power, area and reliability (ESD and latch-up tolerance) requirements for IC designs. These general-purpose I/O circuits include a full set of power pads, corner pad cells, breakers and spacers. These designs are implemented with special design considerations for power supply sequencing requirements. Distributed Power-on-Control (POC) is used during power up and power down of the systems.

GPIO: 1.2V-1.5V-1.8V

Summary

A full range of power pads is provided to enable the system designer different options for separate core power (VDD and VSS) and separate I/O padring power and ground (DVDD and DVSS). The ability to isolate separate power domains is also provided. In addition, the I/O library has a full complement of cells that provide the user with the ability to isolate analog I/O’s and power within the same padring as the digital I/O’s.

Includes

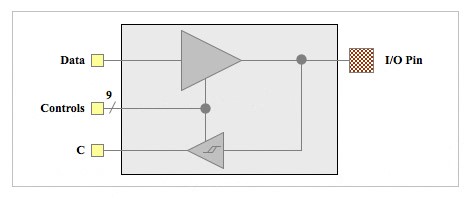

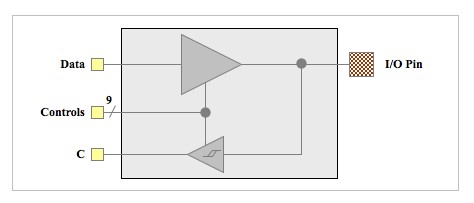

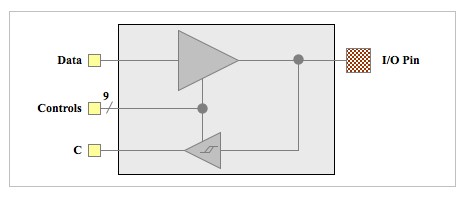

- Programmable GPIO

- Programmable fault-tolerant GPIO

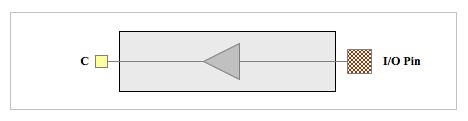

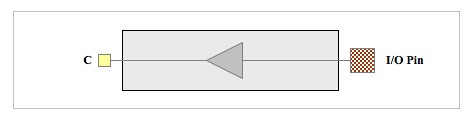

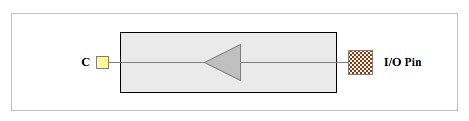

- Input buffer

- Power supplies

- Isolated analog power supplies

- Full complement of support pads

Recommended Operating Conditions

| Description | Min | Nom | Max | Units | |

|---|---|---|---|---|---|

| VDVDD | I/O supply voltage | 1.08 | 1.2 | 1.32 | V |

| 1.35 | 1.5 | 1.65 | V | ||

| 1.62 | 1.8 | 1.98 | V | ||

| TA | Ambient operating temperature | 0 | 25 | 100 | °C |

| VVDD | Core supply voltage | 0.9 | 1.0 to 1.1 | 1.155 | V |

| TJ | Junction temperature | -40 | 25 | 125 | °C |

| VPAD | Voltage at PAD | 0 | - | VDVDD | V |

| VIH | Input logic high | 0.7 * VDVDD | - | VDVDD + 0.3 | V |

| VIL | Input logic low | VDVSS – 0.3 | - | 0.3 * VDVDD | V |

Foundry Support

| Technology | Silicon proven / in production | Under development | Planned |

|---|---|---|---|

| 04/05nm | TSMC | - | - |

| 06/07nm | TSMC | - | - |

| 12nm | TSMC | - | - |

| 14nm | Samsung | - | - |

| 16nm | TSMC | - | - |

| 22nm | GF, TSMC | - | - |

| 28nm | GF, Samsung, TSMC | - | - |

| 40nm | GF, TSMC | - | - |

| 55nm | GF, SMIC, TSMC | - | - |

| 65nm | GF, TSMC | - | - |

| 90nm | GF | - | - |

| 110nm | - | - | - |

| 130nm | - | - | - |

GPIO: 1.5V-1.8V-2.5V

Summary

A full range of power pads is provided to enable the system designer different options for separate core power (VDD and VSS) and separate I/O padring power and ground (DVDD and DVSS). The ability to isolate separate power domains is also provided. In addition, the I/O library has a full complement of cells that provide the user with the ability to isolate analog I/O’s and power within the same padring as the digital I/O’s.

Includes

- Programmable GPIO

- Programmable fault-tolerant GPIO

- Input buffer

- Power supplies

- Isolated analog power supplies

- Oscillators

- Full complement of support pads

Recommended Operating Conditions

Foundry Support

| Technology | Silicon proven / in production | Under development | Planned |

|---|---|---|---|

| 28nm | GF, TSMC | - | - |

| 40nm | TSMC, SMIC | - | - |

| 55nm | GF, TSMC | - | - |

| 65nm | GF, TSMC | - | - |

| 90nm | - | - | - |

| 110nm | - | - | - |

| 130nm | - | - | - |

1.8V-2.5V-2.8V-3.0V-3.3V

Summary

A full range of power pads is provided to enable the system designer different options for separate core power (VDD and VSS) and separate I/O padring power and ground (DVDD and DVSS). The ability to isolate separate power domains is also provided. In addition, the I/O library has a full complement of cells that provide the user with the ability to isolate analog I/O’s and power within the same padring as the digital I/O’s.

Includes

- Programmable GPIO

- Programmable fault-tolerant GPIO

- Input buffer

- Power supplies

- Isolated analog power supplies

- Programmable oscillator

- Full complement of support pads

Recommended Operating Conditions

| Description | Min | Nom | Max | Units | |

|---|---|---|---|---|---|

| VDVDD | I/O supply voltage | 2.97 | 3.3 | 3.63 | V |

| 2.70 | 3.0 | 3.30 | V | ||

| 2.52 | 2.8 | 3.08 | V | ||

| 2.25 | 2.5 | 2.75 | V | ||

| 1.62 | 1.8 | 1.98 | V | ||

| 1.08 | 1.2 | 1.32 | V | ||

| TA | Ambient operating temperature | 0 | 25 | 100 | °C |

| VVDD | Core supply voltage | 0.72 | 0.8 to 1.2 | 1.32 | V |

| TJ | Junction temperature | -40 | 25 | 125 | °C |

| VPAD | Voltage at PAD | 0 | - | VDVDD | V |

| VIH | Input logic high | 0.7 * VDVDD | - | VDVDD + 0.3 | V |

| VIL | Input logic low | VDVSS – 0.3 | - | 0.3 * VDVDD | V |

Foundry Support

| Technology | Silicon proven / in production | Under development |

|---|---|---|

| 7nm | - | TSMC |

| 12nm | TSMC | - |

| 16nm | TSMC | - |

| 22nm | GF | - |

| 28nm | GF, TSMC | - |

| 40nm | GF, TSMC, SMIC | - |

| 55nm | GF | - |

| 65nm | GF, TSMC | - |

| 90nm | GF | - |

| 110nm | GF | - |

| 130nm | GF | - |